For the Operation of Milling Machine Which Motor Is Used

With various attachments milling machines can be used. It was taken off and replaced with a 3PH motor.

What Is Milling Machine Parts Operation Diagram Engineering Choice

Up milling or climb up milling a conventional milling machine is generally used for rough surface cutting operation.

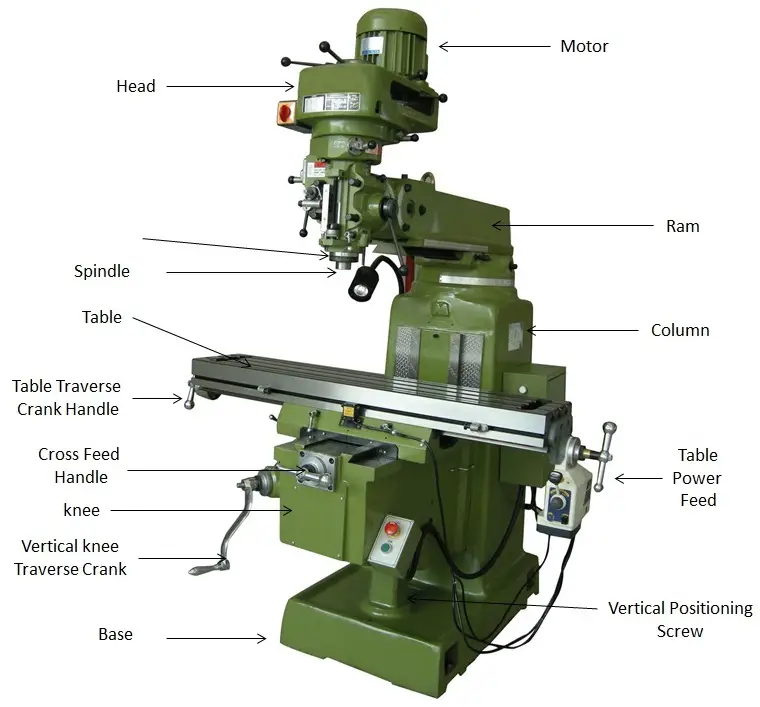

. These cutters are designed to cut with both their side and end. The spindle is driven by an electric motor via gear trains and gear trains are on the column. An adjustable overhead arm containing one or more arbor supports projects forward from the top of the column.

This makes the flat surface at the face of the workpiece. The milling machine removes metal with a revolving cutting tool called a milling cutter. The table movement controls the feed of the workpiece against the rotating cutter.

In this milling operation two or more milling cutter are used together to perform different milling operations simultaneously. The workpiece moves against the cutter and remove the metal from the surface in order to produce the desired shape. There are various milling machine operations used for different kinds of jobs.

One for the cutter one for the work and the third for the longitudinal movement of the cutter. Most milling machines. In this operation cam blank is mounted at the end of the dividing head spindle and the end mill is held in the vertical milling attachment.

This operation is done performed by a face milling cutter mounted on a stub arbor. Thread milling operation is performed in special thread milling machines to produce accurate threads in small or large quantities. The operation thread milling produces threads using thread milling centers.

The cutting tool is called a cutter. This cutter is fixed on a spindle or arbor which revolves at desired speed. An end mill is one of the widely used milling.

For all milling operations. The workpiece is held on a worktable of the machine. MILLING MACHINE OPERATIONS - OD1644 - LESSON 1TASK 1 2.

The bed can also by fed in the x y and z axes manually. It is a very useful machine and mostly used in die making industries. The milling machines can perform almost every milling operation like gear milling thread milling angular milling etc.

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece. Milling is a method used to machine and fabricate specimens from free-cutting material. Included with the motor is.

The usual Mill consists basically of a motor driven spindle which mounts and revolves the milling. See Figure 12 Drilling is accomplished by raising and lowering the entire milling head with. In this operation cutting forces act upward direction.

VM-M25 1-12HP 1 PH motor VM-M20. It is a metal cutting operation using a single-edged or multi-edged tool. The most popular operation done on milling machine is described below.

The arm and arbor supports are used to stabilize long arbors. Therefore DC shunt motor or squirrel cage induction motors are suitable for the operation of milling machines. First understand What is Milling Machine.

This motor was taken off a machine in a home shop. Different cutters are used for profile milling. The spindle is used to hold and drive the cutting tools of a milling machine.

A milling machine removes material from a workpiece by rotating a cutting tool and moving it into the workpiece. Direction for angular and helical milling operations. As we know that milling can perform various operations to convert the work piece into desire shape.

The T-slot milling cutter is used to machine T-slot grooves in worktables fixtures and. The milling cutter conducts a rotary movement and the specimen undergoes a linear motion. Supports can be moved along the.

Milling on a vertical mill is usually accomplished with end mills. It has very high starting torque. The universal machine can be fitted.

The various operation performed by milling machine are described below. Face milling is done on the surface of the workpiece which is placed perpendicular to the axis of the cutter. So it has had very little use.

Jet VM-M25 1-12HP 1 PH motor for JVM 836 milling machine. The operation requires three driving motions in the machine. The video below contain the.

End milling operation. Hence it is used for heavy duty applications such as electric railways mine hoists. This operation is generally used for brassbronze and ferrous materials.

Once an axis is located at a desired position and will no longer be fed it should be locked into position with the gibb locks. The motor cover that adapts mounts the motor on the pulley housing JVM836-42B. It is mounted on the bearings and has the support of the column.

Just a s other the cutters are mounted on the arbor. The plain horizontal milling machines column contains the drive motor and gearing and a fixed position horizontal milling machine spindle. The spindle can be fed up and down with a quill feed lever on the head.

Milling machines come in versions and that is vertical or horizontal. This process helps to create flat surfaces that is horizontal vertical and at a that take the work table as a reference. The machine makes flat and irregularly shaped surfaces and drills bore and cut gears threads and slots.

Milling process is used to fabricate flat curved parallel stepped square and inclined faces and slots. The operation cam milling is used to produce the cam on the milling machine. Milling machines require constant operating speed and low starting torque.

The spindle face lies near the table and has an internal taper machined on it. The milling machines are used to remove metal from the workpiece to get the desired shape with the help of a revolving cutter called known as a milling cutter. Applications of different DC motors are given below.

What Is Milling Machine Operation Parts And Types Mechanical Booster

How Does Milling Machine Work Makinews

Milling Machine Definition Parts Operation Working Principle Application Advantages Notes Pdf

No comments for "For the Operation of Milling Machine Which Motor Is Used"

Post a Comment